Containing a Large Amount of High Chromium Iron Powder, No Crack, No Bubble, No Crack, No Paint on The Weathering Steel Plate

Description

Basic Info.

| Processing | Hot Rolled,Cold Rolled |

| Key Word | No Crack Wear Plate |

| Warranty | Yes |

| Price Negotiable | Yes |

| Provide Sample | Yes |

| Custom Made | Yes |

| Specification | 2+3, 3+3, 5+3, 4+4, 6+5, 8+5, 6+6, 8+6, 8+8, 10+10 |

| Trademark | Atmix |

| Origin | Rizhao Shandong |

| HS Code | 72109000 |

| Production Capacity | 5000 Tons Per Year |

Product Description

Product Description

Wear Resistant Steel Plate Specification | |

| DIN: XAR300,XAR400, XAR450, XAR500, XAR600 |

Thickness | 3-100mm |

Width | 1500-3000mm |

Length | according to customer requirement |

Surface | according to customer requirement |

Package | Standard export seaworthy package,suit for all kinds of transport, |

| Widely used in a variety of architectural and engineering structures,such as |

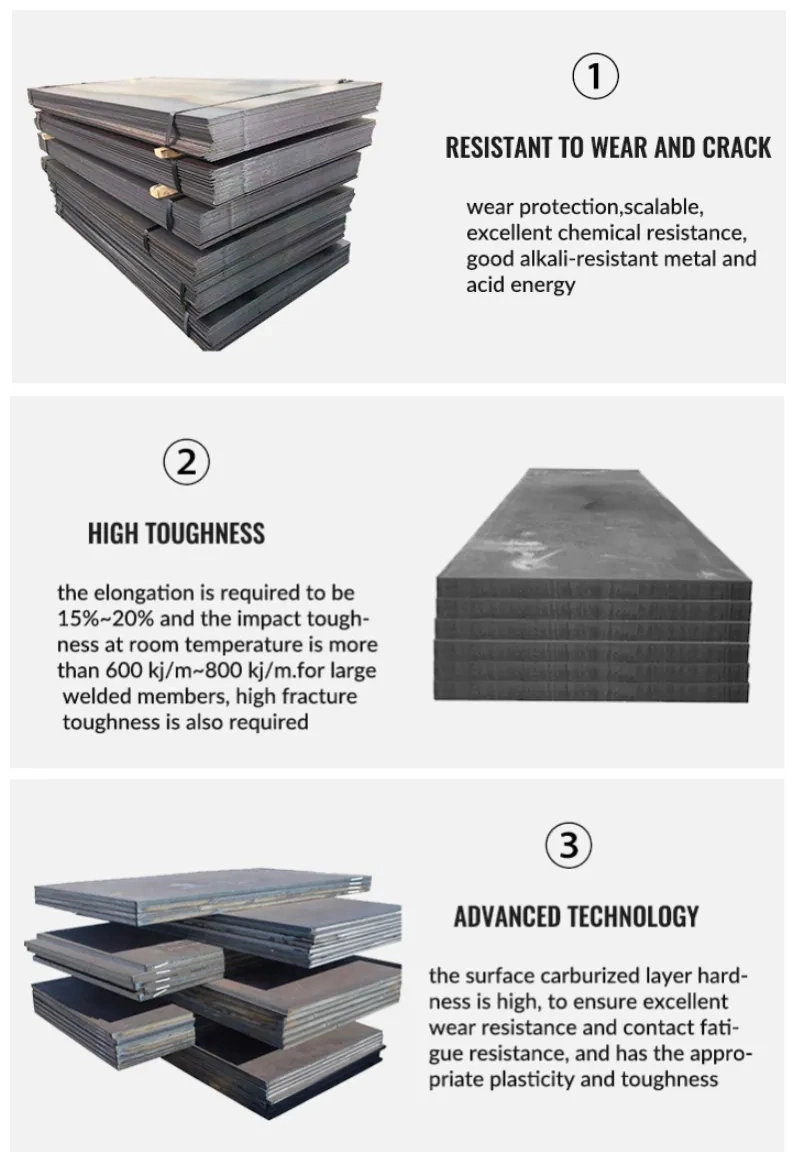

| 1. Excellent wear resistance |

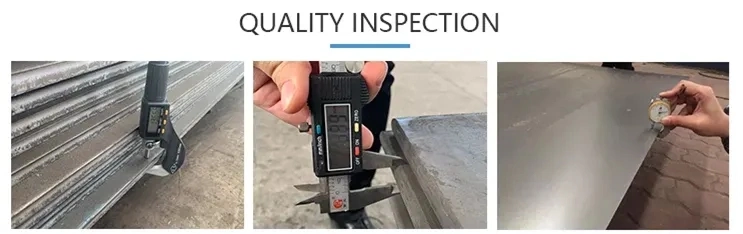

Detailed Photos

Company Profile

Rizhao ATMIX New Materials Co., Ltd. was established in March 2018. The company is located in Shibei Economic Development Zone, Wulian County, Rizhao City, Shandong Province. The company has a superior geographical location and convenient transportation. It is close to Rizhao Port, Dongjiakou Port and other large ports , can provide customers with the most convenient logistics services. The company covers an area of more than 30,000 square meters and izhao ATMIX New Materials Co., Ltd. was established in March 2018. The company is located in Shibei Economic Development Zone, Wulian County, Rizhao City, Shandong Province. The company has a superior geographical location and convenient transportation. It is close to Rizhao Port, Dongjiakou Port and other large ports , can provide customers with the most convenient logistics services. The company covers an area of more than 30,000 square meters and has more than 100 total employees, including more than 30 technical employees of various types. Since its establishment, with huge capital investment and independent technology research and development innovation, the company has produced wear-resistant steel plates, wear-resistant welding wires and related processed parts. It has become a leader in the industry and is widely trusted and supported by users around the world. In the field of wear resistance, we have a professional team to provide customers with wear solutions in harsh working conditions on site, focusing on serving industries such as steel, mining, electric power, ports, petrochemicals, cement, and dredging. The surfacing flux-cored wire and bimetal wear-resistant composite materials independently developed and designed by the company can greatly improve the wear resistance on the basis of the original materials, greatly reduce the replacement rate of the equipment, prolong the service life of the equipment, and reduce the production cost; Favored by major manufacturing industries, our team can provide corresponding materials according to the customer's working conditions, and provide professional equipment, perfect technology and on-site working conditions guidance and services for the application of materials. The company has a complete management system. At present, the company has passed the certification of ISO 9001: 2015 quality management system, ISO 14001: 2015 environmental management system certification, and ISO 45001: 2018 occupational health and safety management system certification. CCS), Det Norske Veritas (DNV), Lloyds Register of Shipping (LR), American Society of Surveyors (ABS), Bureau Veritas (BV) 3Y and 4Y certification. The company has always paid attention to technology research and development investment.

Packaging & Shipping

Prev: Suoyi Spherical Yttrium Oxyfluoride Yof Yf3 Y2o3 for Thermal Spray Coating Plasma Powder

Next: Silicon Nitride Powder Si3n4 Powder 99.9 Silicon Powder Coating

Our Contact