Suoyi 100

Description

Basic Info.

| Model NO. | SY-si3n411 |

| Function | Ceramics |

| Source | Natural Abrasives |

| Particle Size | Powder |

| Hardness | Superabrasive |

| Partice | 15um 20um 45um |

| Transport Package | Drum/Barrel |

| Specification | 25kgs |

| Trademark | SUOYI |

| Origin | China |

| HS Code | 2849200000 |

| Production Capacity | 50000t |

Packaging & Delivery

Package Size 25.00cm * 25.00cm * 20.00cm Package Gross Weight 37.500kgProduct Description

Product Description

Silicon nitride ceramic materials have high thermal stability, strong oxidation resistance and high dimensional accuracy of products. Since silicon nitride is a covalent compound with high bond strength and can form an oxide protective film in the air, it also has good chemical stability. It is oxidized, and is not infiltrated or corroded by many molten metals or alloys such as aluminum, lead, tin, silver, brass, nickel, etc., but can be corroded by molten liquids such as magnesium, nickel-chromium alloy, and stainless steel.

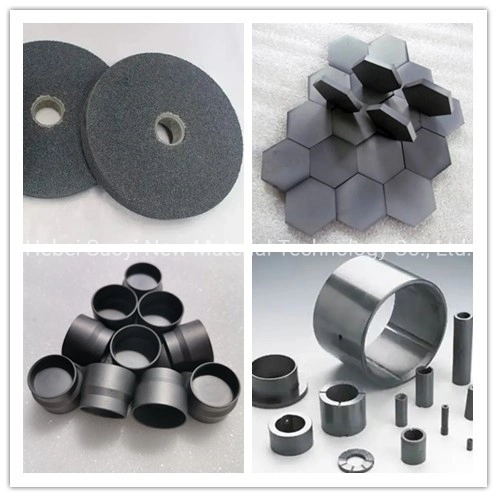

Silicon nitride ceramic materials can be used for high-temperature engineering components, advanced refractory materials in metallurgical industry, corrosion-resistant components and sealing components in chemical industry, cutting tools and cutting tools in machining industry, etc.

Since silicon nitride can form a strong bond with silicon carbide, aluminum oxide, thorium dioxide, boron nitride, etc., it can be used as a bonding material for modification with different ratios.

In addition, silicon nitride can also be used in solar cells. After the silicon nitride film is coated by PECVD method, it can not only be used as an anti-reflection film to reduce the reflection of incident light, but also, during the deposition process of the silicon nitride film, the hydrogen atoms of the reaction product enter the silicon nitride film and the silicon wafer, Played the role of passivation defects. The atomic ratio of silicon nitride to silicon nitride here is not strictly 4:3, but fluctuates within a certain range according to different process conditions, and the physical properties of the film corresponding to different atomic ratios are different.

For ultra-high temperature gas turbines, aircraft engines, electric furnaces, etc.Installation Instructions

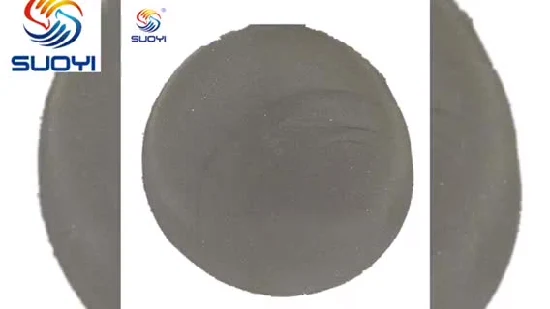

| Name | Silicon Nitride |

| Formula | Si3N4 |

| Appearance | Grey Powder |

| M.W. | 140.28 |

| Density | 3.12 g/cm³ |

| HS Code | 8007003000 |

| Purity | 99.99% |

| Particle size | 20-38 um |

| Application | ceramic, refractory, spray |

| Package | 25kgs/Drum |

| Origin | Hebei,China |

1.As an abrasive, it can be used to make abrasive tools, such as grinding wheels, oilstones, grinding heads, sand tiles, etc.

2.As a metallurgical deoxidizer and high temperature resistant material.

3. High-purity single crystals can be used to manufacture semiconductors and silicon carbide fibers.

Main application: used for wire cutting of 3-12 inch monocrystalline silicon, polycrystalline silicon, potassium arsenide, quartz crystal, etc. Engineering processing materials for the solar photovoltaic industry, semiconductor industry, and piezoelectric crystal industry.

Used in semiconductors, lightning rods, circuit components, high temperature applications, ultraviolet light detectors, structural materials, astronomy, disc brakes, clutches, diesel particulate filters, filament pyrometers, ceramic films, cutting tools, heating elements, nuclear fuels , Jewelry, steel, protective gear, catalyst carrier and other fields.Packaging & ShippingCompany ProfileHebei Suoyi New Material Technology Co., Ltd. was formally established in 2014 and located in Handan, a 3000-year-old city in China. The company has several branch factories, located in Shandong, Henan, Shanxi, etc.The company's main various types are rare earths, rare earth metals.There are currently 268 professionals in the company's headquarters, and more than 1,000 employees are counted in various factories.Compared with other companies, we have a more mature supply chain, professional team and favorable price, etc.And the repurchase rate of cooperating customers is as high as 70%, so you can rest assured to buy the products of Suoyi.After Sales Service1. If it is found that the company sells fake goods, compensation will be USD10000

2. If it is found that the company has reduced the quality of sales, a full refund

3. If you become a customer of our company, we provide technical support

4. All inquiries will be replied within 5 minutes, and solutions will be given within 2 hours

5. We promise to protect the privacy of every customer in an all-round way

6. We promise that every sales manager has more than three years of experience in the industry and sincerely serves every customer

7. In-stock products will be dispatched within 3 days

8. We promise that every order will be strictly inspected before delivery, and will be issued afterFAQ

1. who are we?

We are based in Hebei, China, start from 2014, sell to South America(20.00%), Central America(10.00%), Western Europe(10.00%), Eastern Europe(10.00%), North America(10.00%), Southern Europe(5.00%), Northern Europe(5.00%), Domestic Market(5.00%), SoutheastAsia(5.00%), South Asia(5.00%), Mid East(5.00%), Oceania(5.00%), Eastern Asia(3.00%), Africa(2.00%). There are total about 101-200people in our company.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Zirconia, Alumina, Rare earth oxide, Rare earth fluoride, Rare earth chloride,Calcium Series

4. why should you buy from us not from other suppliers?

HEBEI SUOYI NEW MATERIAL TECHNOLOGY CO.,LTD is a professional manufacture high purity inorganic salts .High purity rare earth series and other products etc. We have factory. We are sure we can supply the high quality products with competitive price.

5. what services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, DDP, DDU, Express Delivery;

Accepted Payment Currency: USD;

Accepted Payment Type: T/T,L/C,D/P D/A, MoneyGram, Credit Card, PayPal, Western Union;

Language Spoken: English, Chinese

Prev: Titanium Carbide Tic Particle Used for Powder Metallurgy Production Metal Ceramic

Next: Microcarbon Ferrochrome 65V6 65V3 70V3 Welding Industry Powder Metallurgy

Our Contact